In today’s fast-paced manufacturing environment, efficiency, precision, and reliability are key. Resistance spot welding (RSW) has long been a cornerstone in industries ranging from automotive to electronics, offering fast, repeatable, and high-quality metal joining solutions. For manufacturers, OEMs, and automation integrators, understanding the principles, applications, and best practices of RSW is essential for optimizing production lines. Heron Welder, a global leader in resistance welding machines and automated welding solutions, provides advanced systems to meet these demands with precision and reliability.

What is Resistance Spot Welding?

Resistance spot welding is a metal joining process that uses electrical resistance and heat to fuse two or more overlapping metal sheets at discrete points. Unlike traditional welding, which melts the entire joint, spot welding focuses heat precisely at the weld nugget, creating a strong, localized bond without deforming surrounding material.

The process involves three main components:

- Electrodes: Typically copper alloy tips that conduct electrical current into the metal sheets.

- Electrical Current: A high-amperage current passes through the metal sheets, generating heat due to electrical resistance.

- Pressure: Mechanical force applied by the electrodes ensures proper contact and forms the weld nugget.

The combination of current, pressure, and time known as the welding schedule determines the quality, strength, and consistency of the weld.

Key Advantages of Resistance Spot Welding

Resistance spot welding offers several advantages that make it indispensable for modern industrial manufacturing:

- Speed and Efficiency: Spot welds can be completed in fractions of a second, making the process ideal for high-volume production.

- Consistency and Repeatability: Automated RSW machines ensure uniform welds, reducing defects and material waste.

- Minimal Material Distortion: Localized heating prevents warping or structural compromise of the surrounding metal.

- Safety and Clean Process: No filler material or shielding gases are needed, reducing consumables and environmental impact.

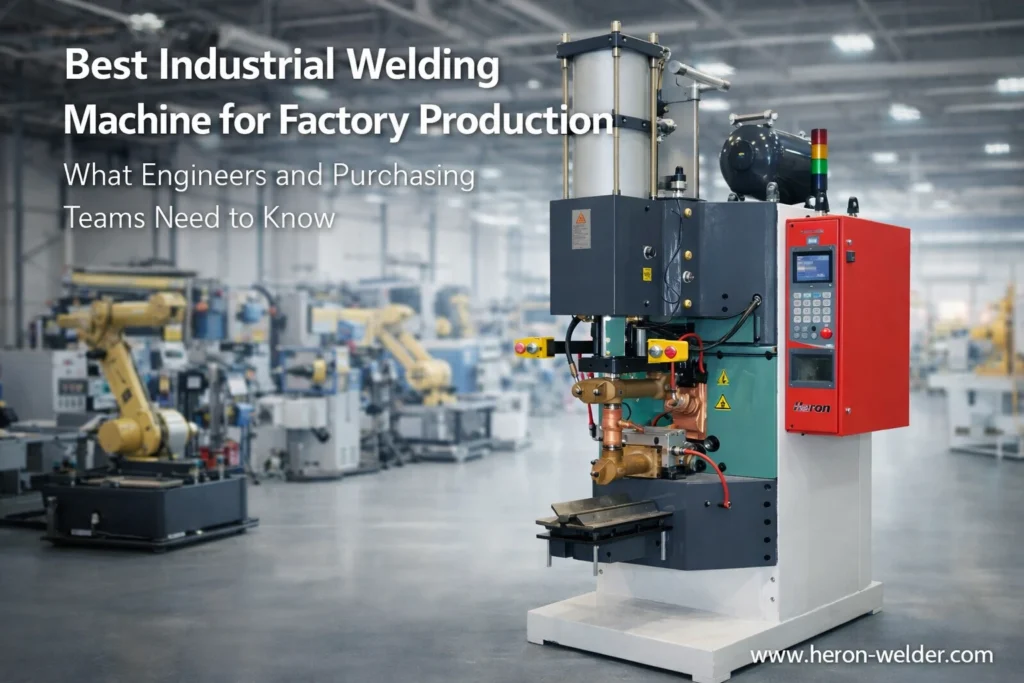

Heron Welder’s resistance spot welding solutions are engineered for precision, combining robust mechanical design with advanced control systems to deliver superior weld quality across diverse industrial applications.

Applications of Resistance Spot Welding

RSW is widely used across industries that require strong, reliable sheet metal joints:

1. Automotive Manufacturing

Spot welding is the backbone of vehicle body assembly. Door panels, chassis components, and roof structures are commonly joined using RSW, ensuring safety, rigidity, and corrosion-resistant bonds.

2. Electronics and Electrical Enclosures

For assembling battery packs, switchgear, and electronic housings, RSW provides precise welds that maintain electrical conductivity and structural integrity.

3. Appliance and Consumer Goods Production

Washing machines, refrigerators, and metal furniture often rely on spot welding for efficient, cost-effective assembly of thin-gauge metals.

4. Aerospace and Heavy Machinery

Advanced resistance spot welding machines are capable of joining high-strength steels and aluminum alloys used in aerospace and industrial equipment manufacturing.

Comparing Resistance Spot Welding with Other Welding Techniques

While resistance spot welding is highly efficient for sheet metal, it’s important to understand how it compares to alternative processes:

| Welding Method | Key Advantage | Limitations |

|---|---|---|

| Resistance Spot Welding | Fast, consistent, minimal distortion | Limited to overlapping sheets; thickness constraints |

| MIG/MAG Welding | Suitable for thicker metals; versatile | Slower for high-volume sheet assembly |

| TIG Welding | High-quality, precise welds | Labor-intensive; not ideal for mass production |

| Laser Welding | Excellent for thin metals; minimal heat-affected zone | Higher capital cost; more complex setup |

Heron Welder provides RSW machines that integrate easily with automation lines, offering superior speed and efficiency compared to manual welding methods, while maintaining high-quality welds.

Best Practices for Resistance Spot Welding

Achieving consistent, high-quality spot welds requires attention to several critical factors:

- Electrode Maintenance: Regular inspection and dressing of electrodes prevent excessive wear and ensure even welds.

- Optimized Welding Schedule: Adjusting current, pressure, and time according to material type and thickness is essential.

- Material Preparation: Clean, properly aligned sheets improve electrical contact and weld reliability.

- Automation Integration: Automated RSW systems reduce human error, increase throughput, and maintain repeatable weld quality.

- Monitoring and Quality Control: Advanced controllers, like those offered by Heron Welder, monitor real-time parameters to detect anomalies and prevent defective welds.

Why Choose Heron Welder for Resistance Spot Welding

As a trusted global manufacturer of industrial welding equipment, Heron Welder offers a full range of RSW machines, from manual units to fully automated systems integrated into production lines. Key advantages include:

- Advanced Controllers: Precision monitoring and programmable welding schedules for consistent quality.

- Customizable Solutions: Machines tailored to specific material types, thicknesses, and production volumes.

- Automation Support: Seamless integration with robotic cells for high-volume manufacturing.

- Global Expertise: Years of experience delivering reliable welding and metal-joining solutions to OEMs and industrial manufacturers.

FAQs About Resistance Spot Welding

Q1: What materials can be welded using resistance spot welding?

A1: Primarily sheet metals such as steel, stainless steel, and aluminum alloys. Material thickness and conductivity affect the weld parameters.

Q2: How long does a typical spot weld take?

A2: Weld time is usually between 0.1 and 1 second, depending on material and thickness.

Q3: Can RSW be automated for high-volume production?

A3: Yes. Robotic RSW systems offer high repeatability and throughput, ideal for automotive, electronics, and appliance manufacturing.

Q4: How is weld quality ensured?

A4: Through proper welding schedules, electrode maintenance, and advanced monitoring systems that detect current, pressure, and temperature variations.

Q5: Is RSW suitable for thick metals?

A5: RSW is most effective for thin to medium-thickness metals. For thicker materials, projection welding or alternative methods may be more appropriate.

Conclusion: Elevate Your Manufacturing with Heron Resistance Spot Welding

For manufacturers seeking precision, speed, and reliability, resistance spot welding is a proven solution. Heron Welder’s advanced RSW machines combine cutting-edge technology with industrial-grade durability, helping OEMs, automation integrators, and factory managers optimize production lines and maintain consistent weld quality.

Ready to enhance your metal-joining processes? Contact Heron Welder today to explore customized resistance spot welding solutions tailored to your production needs.