Dubai’s industrial sector has experienced remarkable growth over the past decade, spanning manufacturing, oil and gas, construction, aerospace, and automotive industries. As operations scale, one of the critical challenges faced by industrial operators is ensuring the longevity and reliability of machinery and equipment. High operational temperatures, corrosion, abrasion, and chemical exposure can significantly reduce equipment lifespan. To address these challenges, Dubai industries are increasingly adopting precision metal surface solutions, including advanced coating and cladding techniques, to enhance durability, performance, and cost-efficiency.

The Importance of Metal Surface Solutions

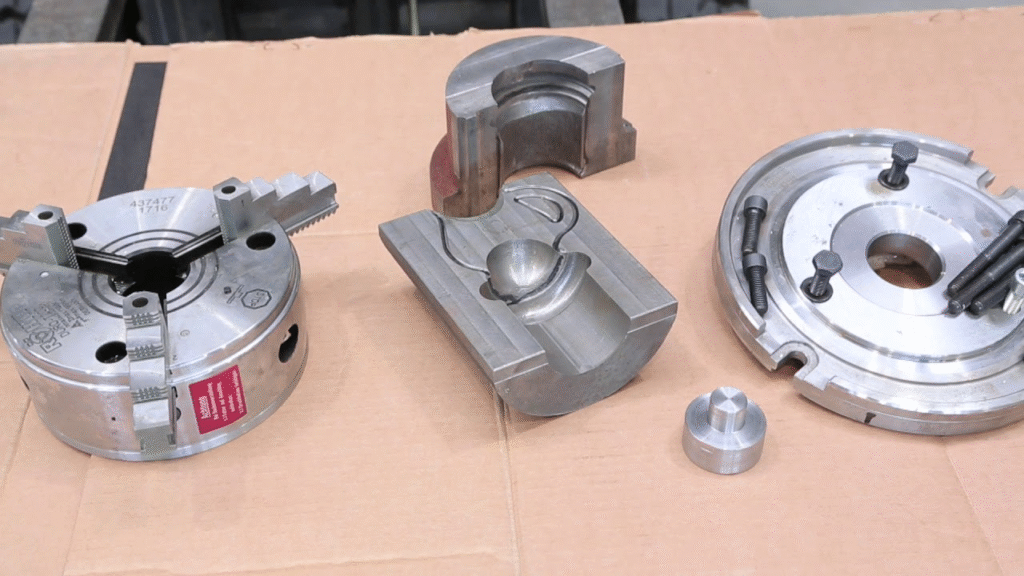

Industrial machinery and equipment endure continuous stress from mechanical, chemical, and environmental factors. Without proper surface protection, components such as valves, pumps, pipelines, and structural parts can wear prematurely, leading to operational downtime, costly repairs, and reduced safety. Precision metal surface solutions, including PTA cladding, laser cladding, and thermal spray coatings, provide a proactive approach to mitigating these risks.

These solutions not only protect equipment from corrosion and wear but also improve efficiency, reduce maintenance costs, and ensure compliance with international quality and safety standards. In Dubai’s industrial environment, where high temperatures and harsh conditions are common, surface protection has become a key investment for long-term operational reliability.

NOTE: Dubai industries had extended machinery lifespan using PTA Cladding. The technique had improved corrosion and wear resistance, reducing downtime and maintenance costs. Raysun had delivered expert surface solutions tailored to industrial requirements. Contact Raysun Techno Industries LLC today for reliable PTA cladding services in Dubai.

Key Precision Surface Techniques

Several advanced techniques are used to extend equipment life in Dubai’s industrial sector:

1. Plasma Transferred Arc (PTA) Cladding

PTA cladding is a precise method for depositing wear-resistant and corrosion-resistant materials onto metal surfaces. It enhances surface hardness, reduces abrasion, and protects critical components in pipelines, pumps, and valves. Dubai manufacturers and oil & gas operators rely on PTA cladding to maintain equipment performance under high-pressure and high-temperature conditions.

2. Laser Cladding

Laser cladding uses a focused laser beam to melt and bond a metallic coating onto a base metal. This method ensures minimal heat distortion, precise material deposition, and excellent metallurgical bonding. Laser cladding is ideal for aerospace, automotive, and high-precision manufacturing applications in Dubai, where tolerance and performance are critical.

3. Thermal Spray Coatings

Thermal spray coatings involve applying molten or semi-molten materials to a surface to form a protective layer. These coatings enhance wear, corrosion, and heat resistance. Industries in Dubai, including power generation and chemical manufacturing, use thermal spray coatings to protect equipment operating under aggressive conditions.

4. Hard Facing

Hard facing is the process of depositing a harder or tougher material on equipment surfaces to resist wear and abrasion. This method is particularly effective for heavy machinery, crushers, and industrial valves. Dubai construction and manufacturing sectors have benefited from hard-facing techniques to improve component lifespan.

Benefits of Precision Metal Surface Solutions

Implementing advanced surface solutions in Dubai industries offers multiple advantages:

- Extended Equipment Life: Coatings and cladding protect machinery from wear, corrosion, and environmental damage.

- Reduced Maintenance Costs: Enhanced durability reduces the frequency of repairs and replacements.

- Operational Efficiency: Well-protected equipment operates reliably, minimizing downtime and production losses.

- Improved Safety: Reduced risk of failure enhances worker and operational safety.

- Sustainability: Longer equipment lifespan reduces material waste and supports eco-friendly industrial practices.

Industrial Applications in Dubai

Dubai industries have successfully applied precision metal surface solutions across multiple sectors:

- Oil and Gas: PTA cladding protects pipelines, valves, and pumps from high pressure, corrosion, and chemical attack.

- Construction: Hard-facing and coating techniques enhance the durability of heavy machinery, cranes, and structural steel.

- Aerospace: Laser cladding delivers precision and strength to aircraft components subjected to high stress.

- Manufacturing: Thermal spray coatings and surface treatments improve wear resistance in production equipment and machinery.

These applications demonstrate how precision surface solutions help Dubai industries maintain competitiveness, reduce operational costs, and deliver consistent quality.

Partnering with Expert Solution Providers

Selecting a reliable provider for metal surface solutions is essential. Companies like Raysun Techno Industries LLC specialize in advanced surface protection techniques, offering PTA cladding, laser cladding, thermal spray coatings, and hard-facing solutions. Their expertise ensures Dubai industrial operators receive customized solutions, certified processes, and technical support for long-term operational reliability.

Partnering with experienced providers guarantees proper material selection, optimal deposition techniques, and adherence to international standards, ultimately extending equipment life and protecting investment.

Best Practices for Maximizing Equipment Life

To ensure the effectiveness of precision surface solutions, Dubai industries follow several best practices:

- Assess Operating Conditions: Analyze wear, corrosion, and environmental factors affecting machinery.

- Select Appropriate Surface Solution: Choose between PTA cladding, laser cladding, thermal spray, or hard-facing based on equipment needs.

- Regular Maintenance: Inspect coated or clad surfaces periodically to ensure continued protection.

- Work with Certified Providers: Engage experienced companies like Raysun Techno Industries LLC to deliver reliable, high-quality surface solutions.

Conclusion

Precision metal surface solutions have become a cornerstone for extending equipment life in Dubai’s industrial sector. Techniques such as PTA cladding, laser cladding, thermal spray coatings, and hard-facing protect machinery from wear, corrosion, and environmental damage, enhancing reliability and reducing maintenance costs. By partnering with trusted providers like Raysun Techno Industries LLC, Dubai industries can implement state-of-the-art surface protection solutions, ensuring long-term efficiency, safety, and industrial growth in a competitive market.

For More Information Visit Us: trackcourier