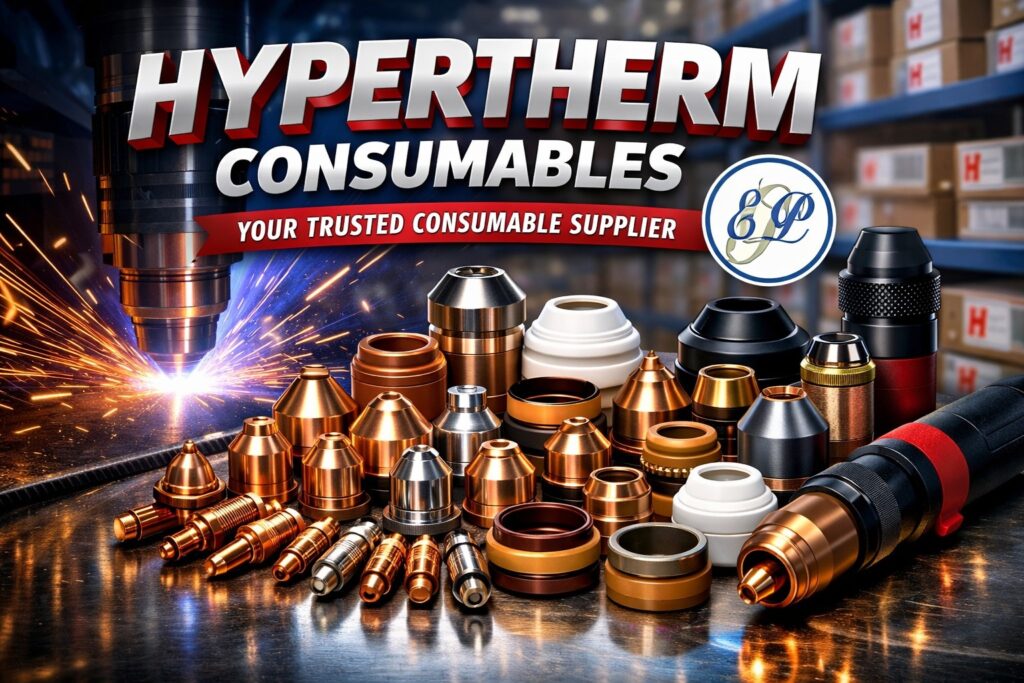

Plasma cutting is one of the most effective and widely used methods for cutting metal in industries such as fabrication, construction, automotive, and manufacturing. Hypertherm is a trusted and well known brand in plasma cutting technology. While Hypertherm machines are built for high performance, the quality of cutting also depends heavily on the consumables used in the plasma torch.

Using the correct Hypertherm consumables ensures clean cuts, better accuracy, and longer machine life. In this blog, we will explain in simple words which Hypertherm consumables you should use for the best results, why they matter, and how choosing the right Plasma Cutter Consumable Suppliers can improve overall cutting performance.

Understanding Hypertherm Consumables

Hypertherm consumables are the parts inside a plasma torch that wear out during normal use and need to be replaced regularly. These parts are exposed to high heat, electrical current, and gas pressure, which causes gradual wear.

The most common Hypertherm Consumable & Parts include:

- Electrodes

- Nozzles

- Shields

- Swirl rings

- Retaining caps

Each of these parts plays an important role in forming and controlling the plasma arc that cuts through metal. Using the correct consumables designed specifically for Hypertherm machines helps maintain stable cutting performance.

Why the Right Consumables Are Important

Many cutting problems are caused by using incorrect or worn consumables. When the right consumables are used, you get:

- Cleaner and smoother cuts

- Better cutting accuracy

- Reduced slag and rework

- Faster cutting speeds

- Longer consumable and machine life

On the other hand, using low quality or mismatched consumables can lead to uneven cuts, excessive slag, and frequent machine stoppages. This is why choosing genuine Hypertherm Consumable & Parts from reliable Plasma Cutter Consumable Suppliers is essential.

Best Hypertherm Consumables for Optimal Performance

Below is a detailed look at the key consumables and how choosing the right ones improves cutting results.

Electrodes

Electrodes carry the electrical current that creates the plasma arc. They are one of the most important consumables in a plasma cutting system.

Best choice:

Always use original Hypertherm electrodes made from high quality materials. These electrodes provide consistent arc performance and last longer under high temperatures.

Why it matters:

A worn or poor quality electrode can cause an unstable arc, leading to rough cuts and damage to other consumables.

Nozzles

Nozzles shape and direct the plasma arc toward the metal being cut. They control the width and focus of the cut.

Best choice:

Use Hypertherm nozzles designed specifically for your plasma cutter model and cutting application.

Why it matters:

High quality nozzles produce precise cuts with smooth edges. Incorrect or damaged nozzles can result in wider cuts and excessive slag.

Shields

Shields protect the nozzle and electrode from sparks, heat, and molten metal during cutting.

Best choice:

Original Hypertherm shields that match your nozzle and cutting setup.

Why it matters:

A damaged or incorrect shield can allow debris to enter the torch, reducing the life of other consumables and affecting cut quality.

Swirl Rings

Swirl rings control the flow of gas around the plasma arc. This helps stabilize the arc and improves cutting accuracy.

Best choice:

Hypertherm swirl rings designed for the correct gas type and pressure required by your machine.

Why it matters:

Proper gas flow ensures a stable arc, cleaner cuts, and reduced wear on other consumables.

Retaining Caps

Retaining caps hold all the consumables securely in place inside the torch.

Best choice:

Use retaining caps that are compatible with your specific Hypertherm torch and consumable set.

Why it matters:

A loose or poorly fitted retaining cap can cause uneven wear and inconsistent cutting results.

How to Choose the Right Consumables for Your Job

Selecting the right Hypertherm Consumable & Parts depends on several factors.

Know Your Plasma Cutter Model

Each Hypertherm plasma cutter model uses specific consumables. Always refer to the machine manual or product guide to select the correct parts.

Match Consumables to Material Type

Different metals such as mild steel, stainless steel, and aluminum may require different consumables or gas settings. Make sure your consumables are suitable for the material you are cutting.

Consider Material Thickness

Thicker materials place more stress on consumables. For heavy duty cutting, use consumables designed for higher amperage and longer life.

Cutting Frequency and Environment

If you cut metal frequently or work in demanding environments, investing in high quality consumables will reduce downtime and improve productivity.

Importance of Choosing Reliable Plasma Cutter Consumable Suppliers

Even the best consumables will not deliver good results if they are not genuine. This is why selecting trusted Plasma Cutter Consumable Suppliers is so important.

Reliable suppliers provide:

- Genuine Hypertherm Consumable & Parts

- Correct part recommendations

- Technical support and guidance

- Consistent product quality

- Warranty and after sales service

Buying from untrusted sources may result in counterfeit or low quality parts, which can damage your machine and increase operating costs.

Common Mistakes to Avoid

Many users unknowingly reduce cutting performance by making simple mistakes, such as:

- Using consumables past their usable life

- Mixing consumables from different brands

- Installing parts incorrectly

- Ignoring routine inspection and maintenance

Avoiding these mistakes helps maintain consistent cutting quality and extends the life of both consumables and equipment.

Tips for Extending Consumable Life

To get the best value from your consumables, follow these simple tips:

- Inspect consumables regularly for wear or damage

- Replace parts before they fail completely

- Keep the torch clean and free of debris

- Store consumables in a clean, dry place

- Follow Hypertherm maintenance guidelines

Proper care reduces downtime and improves overall cutting performance.

Conclusion

Using the correct Hypertherm Consumable & Parts is essential for achieving the best plasma cutting results. High quality electrodes, nozzles, shields, swirl rings, and retaining caps help produce clean, accurate, and consistent cuts.

Buying from trusted Plasma Cutter Consumable Suppliers ensures that you receive genuine parts that fit properly and last longer. With the right consumables and proper maintenance, your Hypertherm plasma cutter will deliver reliable performance and long term cost savings.