In modern industrial environments, compressed air is often referred to as the fourth utility, standing alongside electricity, water, and gas. From manufacturing and automotive workshops to food processing and pharmaceutical plants, compressed air powers tools, machines, and processes that keep businesses running smoothly. However, the quality of compressed air is just as important as its availability. This is where a Compressed Air Filter becomes a critical component.

A compressed air filter ensures that the air flowing through your system is clean, dry, and free from harmful contaminants. Without proper filtration, compressed air can carry dust, oil vapors, moisture, and microorganisms that damage equipment, reduce efficiency, and compromise product quality. In this in-depth guide, we will explore what a compressed air filter is, how it works, its types, benefits, and how to choose the right one for your application.

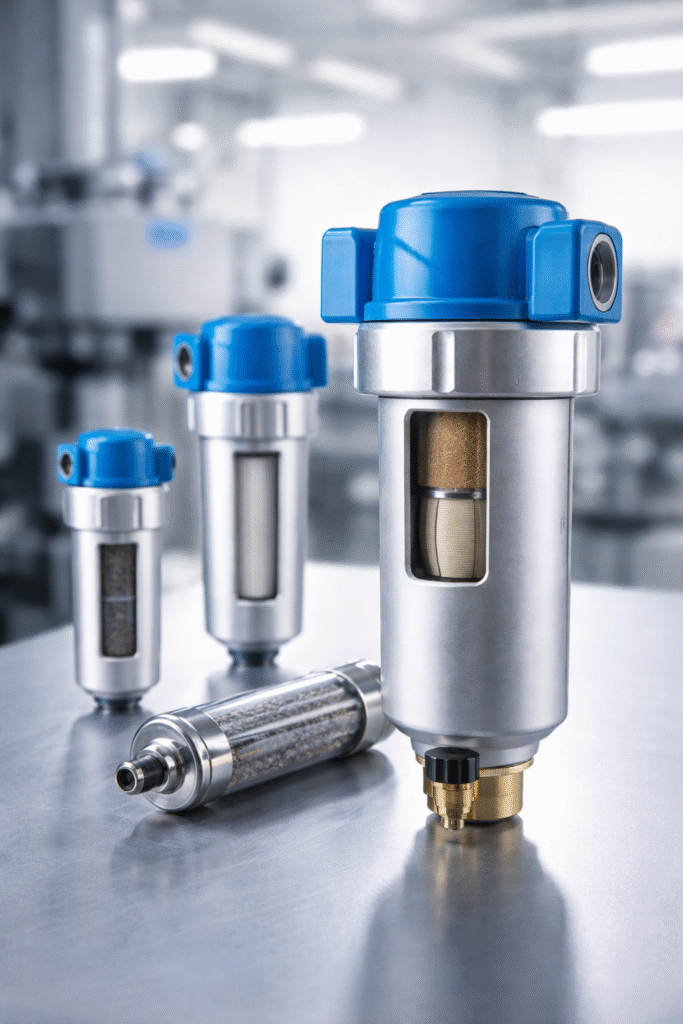

What Is a Compressed Air Filter?

A Compressed Air Filter is a device installed within a compressed air system to remove contaminants such as solid particles, water droplets, oil aerosols, and odors from the air. Ambient air naturally contains impurities, and when this air is compressed, the concentration of contaminants increases significantly.

Without filtration, these impurities can:

- Corrode pipes and pneumatic tools

- Cause equipment failure and downtime

- Affect the quality of end products

- Increase maintenance and energy costs

A compressed air filter acts as a protective barrier, ensuring that only clean air reaches downstream equipment and processes.

Why Compressed Air Filtration Is Essential

Many industries rely on precision, cleanliness, and consistency. Even microscopic contaminants can create serious problems in sensitive applications. Installing the right compressed air filter provides multiple operational and financial advantages.

1. Equipment Protection

Contaminants like rust particles, dirt, and oil can wear down valves, cylinders, and actuators. Clean air reduces friction, prevents clogging, and extends the lifespan of pneumatic components.

2. Improved Product Quality

In industries such as food and beverage, electronics, and pharmaceuticals, air quality directly affects the final product. A compressed air filter prevents contamination that could lead to product rejection or regulatory issues.

3. Energy Efficiency

Blocked or dirty systems require compressors to work harder, consuming more energy. Proper filtration ensures optimal airflow and reduces unnecessary pressure drops.

4. Reduced Maintenance Costs

By keeping contaminants out of the system, compressed air filters lower the frequency of repairs, part replacements, and unplanned downtime.

Common Contaminants in Compressed Air

Understanding what needs to be filtered helps in selecting the correct compressed air filter.

- Solid Particles: Dust, rust, and scale from pipes

- Water: Moisture formed during compression and cooling

- Oil: Lubricant aerosols and vapors from compressors

- Microorganisms: Bacteria and mold in humid environments

- Odors and Gases: Hydrocarbon vapors and chemical fumes

Each contaminant requires a specific type of filtration for effective removal.

Types of Compressed Air Filters

Not all compressed air filters serve the same purpose. Different filter types are designed to remove different contaminants.

1. Particulate Filters

These filters remove solid particles such as dust, dirt, and rust. They are typically the first stage of filtration and protect downstream equipment from mechanical damage.

2. Coalescing Filters

Coalescing compressed air filters remove fine oil aerosols and water droplets by merging them into larger droplets that can be drained away. They are essential in systems where oil-free air is required.

3. Activated Carbon Filters

These filters remove oil vapors, odors, and gaseous contaminants. Activated carbon compressed air filters are commonly used in food processing, pharmaceutical, and breathing air applications.

4. High-Efficiency Filters

Designed for critical applications, these filters capture extremely fine particles and aerosols, often down to sub-micron levels.

5. Sterile and Microbial Filters

Used in medical, biotech, and food industries, these compressed air filters remove bacteria and microorganisms to ensure sterile air delivery.

How a Compressed Air Filter Works

The working principle of a compressed air filter depends on its design, but most follow a similar process:

- Air Entry: Compressed air enters the filter housing.

- Deflection and Separation: Larger particles and water droplets are separated using centrifugal force.

- Filtration Media: Fine contaminants are captured by filter elements made from fibrous or layered materials.

- Condensate Collection: Liquids accumulate at the bottom and are removed through manual or automatic drains.

- Clean Air Output: Filtered air exits the system and flows to downstream equipment.

This multi-stage process ensures consistent air quality throughout the system.

Applications of Compressed Air Filters

Compressed air filters are used across a wide range of industries:

- Manufacturing: Powering tools, automation systems, and machinery

- Automotive: Painting, tire inflation, and assembly lines

- Food & Beverage: Packaging, bottling, and processing

- Pharmaceuticals: Cleanrooms and production environments

- Electronics: Preventing dust and moisture damage

- Textiles: Ensuring smooth machine operation

Each application has unique air quality requirements, making proper filter selection essential.

Choosing the Right Compressed Air Filter

Selecting the correct compressed air filter involves more than just matching pipe size. Consider the following factors:

Air Quality Standards

Industries often follow ISO standards for compressed air quality. Identify the required purity level for your application.

Flow Rate and Pressure

Ensure the filter can handle your system’s airflow without causing excessive pressure drop.

Type of Contaminants

Determine whether you need to remove particles, oil, water, or odors—and choose filters accordingly.

Operating Conditions

Temperature, humidity, and operating pressure affect filter performance and lifespan.

Maintenance Requirements

Easy-to-replace filter elements and automatic drains can significantly reduce maintenance efforts.

Maintenance Tips for Compressed Air Filters

Proper maintenance ensures consistent performance and long service life:

- Inspect filters regularly for pressure drop

- Replace filter elements as recommended by the manufacturer

- Drain condensate frequently to prevent re-contamination

- Monitor air quality at critical points

- Keep maintenance records for system optimization

Neglecting filter maintenance can compromise air quality and negate the benefits of filtration.

Compressed Air Filter vs. Air Dryer

While both improve air quality, they serve different functions. A compressed air filter removes contaminants such as particles and oil, while an air dryer primarily removes moisture. For optimal results, filters and dryers are often used together in a complete air treatment system.

Future Trends in Compressed Air Filtration

Advancements in filtration technology are making compressed air filters more efficient and sustainable. Modern systems feature smart sensors, energy-efficient designs, and eco-friendly filter materials. These innovations help businesses reduce carbon footprints while maintaining high air quality standards.

Conclusion

A Compressed Air Filter is not just an accessory—it is a vital component that protects equipment, improves product quality, and enhances overall system efficiency. By removing harmful contaminants from compressed air, these filters ensure reliable operations across a wide range of industries.

Investing in the right compressed air filter and maintaining it properly can lead to long-term cost savings, improved performance, and compliance with industry standards. Whether you operate a small workshop or a large industrial facility, clean compressed air is essential—and it all starts with effective filtration.

Other Blogs Article – https://trackcourier.xyz/